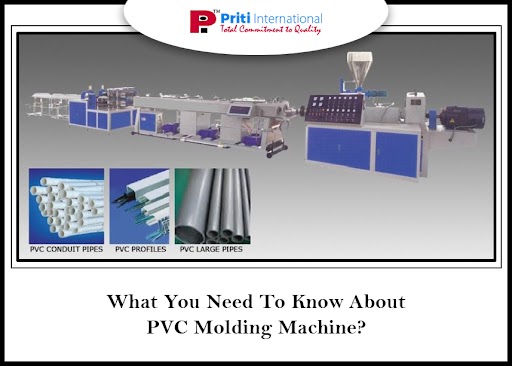

HDPE PVC Molding machine helps in the production of plastic goods during the moulding process. Know about the process involved in detail in this blog.

The inclusion of HDPE moulding machine to the production of plastic goods is exemplary. In addition, there are different types of blow moulding machinery used to make PET (polyethylene terephthalate) bottles. Manufacturers must decide which injection stretch blow moulding procedure to utilise to make plastic bottles.

The benefits of being able to select the best process include raising productivity, lowering costs, and reducing the number of cycles needed to make these materials. However, you must choose because of the substantial variations between single-stage and two-stage moulding procedures.

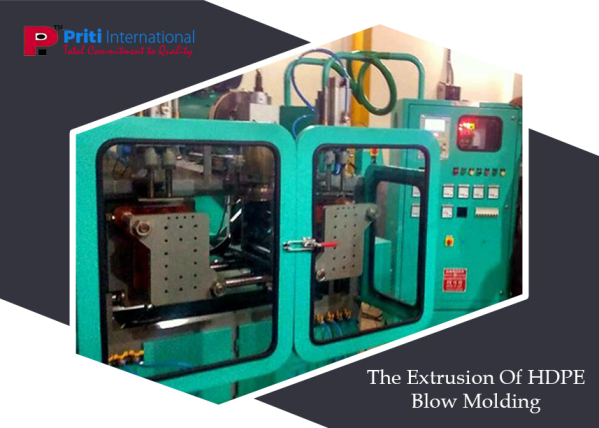

Blow Molding Machines

Bottles made of both plastic and glass production use blow moulding machines. Before the plastic components come together to form a bottle. It makes use of a number of techniques to create hollow portions.

There are three main procedures that attempt to make this possible:

- Stretch blow moulding by injection

- Blower injection moulding

- Blower extrusion moulding

The injection stretch blow moulding procedure is necessary to produce PET or plastic bottles, even though each of these will result in the manufacturing of a bottle.

WHAT IS THE PROCESS OF SINGLE-STAGE BLOW MOLDING?

The fact that reforms are complete, stretched and blown on the same machine before cooling gives single-stage processes their name.

Therefore, it may also be that single-stage PET blow moulding machines use a direct process. The integration of the injection moulding system and blow moulding station into a single machine is responsible for this degree of capability.

The steps that make up the single-stage method

The following steps discuss the raw ingredients in bottles using the single-stage method:

- PET materials are dried and dehumidified.

- Melting and injecting the raw components through the injection nozzle into the perform mould

- 120 ° Celsius cooling of the molten material in the preform mould

- Stretch moulding is started by moving the hot preform mould to a bottle mould.

A Two-Stage Blow Molding Process: What Is It?

Two machines find application in the two-stage injection stretch blow moulding process. These are the stretch blow moulding machine and injection moulding system. In this case, the plastic at first goes into a preform that has fully cooled before being sent to the second machine.

The preform can be sold to a third party even before it is blown using the second machine, and it often includes the bottle’s thread and neck.

Activities Related To The Two-Stage Method

PET materials go through drying and dehumidifying.

Using an injection machine, molten raw materials go into a preform mould.

- Melting PET cooling to ambient temperature

- Perform processing by a finishing device

- Transferring the preform to stretch blow moulding machines that are still heating up

- Using metal blow moulds to inject high-pressure air into bottles

Conclusion

Do you have an interest in purchasing HDPE and PVC moulding machine to streamline your work process? The best of these machines are provided by Priti International, so get in touch.